Our Products

Explore our range of high-quality valves and flanges for diverse industries.

our products

Valves

A Valve is defined as any devices that regulate, controls, directs the flow of liquids (fluids) & gases through process piping by opening, closing, or obstructing ports or passageways. There are numerous types of valves exits and they are principally classified in three different groups; Linear Motion, Rotary Motion, and Quarter-Turn Valves. Again, these become vast in combination subject to its applications.

Gate Valves

Gate valves are essential for on/off flow control in pipelines. Their robust design ensures dependable operation in applications requiring full, unobstructed flow. Commonly used in Oil & Gas, Petrochemical, and Water Treatment.

Key Features

More Info

- Minimal pressure drop when fully open.

- Suitable for high-pressure, high-temperature conditions.

- Various configurations such as bolted bonnet and pressure seal designs.

Applications

More Info

- Pipeline isolation in refineries and chemical plants.

- Water supply systems and distribution networks.

- High-pressure steam and gas systems.

Globe Valves

Globe valves are the go-to solution for flow regulation and throttling, offering precise control with linear motion.

Key Features

More Info

- Excellent throttling capabilities.

- Durable under high-pressure and high-temperature operations.

- Variants include T-pattern, Y-pattern, and angle designs.

Applications

More Info

- Cooling water systems in power plants.

- Desalination plants.

- Fuel handling systems.

Check Valves

Check valves ensure unidirectional flow, preventing backflow that could disrupt processes or damage equipment.

Key Features

More Info

- Automatic operation with no external controls required.

- Swing Check Valves: Ideal for low-pressure applications and horizontal pipelines.

- Dual Plate Check Valves: Compact and lightweight, suitable for high-pressure applications.

- Piston Check Valves: Designed for precise control and fast closure in high-pressure systems.

Applications

More Info

- Pump discharge pipelines.

- Offshore drilling and marine systems.

- Chemical and water treatment plants.

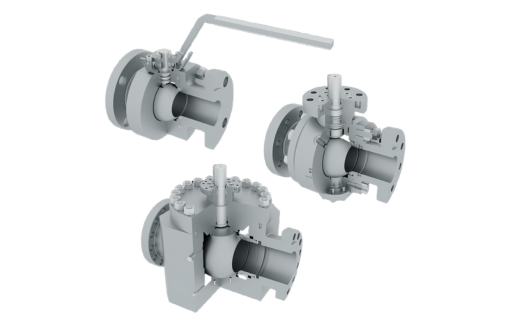

Ball Valves

Ball valves provide excellent sealing and rapid shutoff for critical applications.

Key Features

More Info

• Low torque operation for quick opening/closing.

• Floating Ball Valves: Simple design for low-pressure applications.

• Trunnion-Mounted Ball Valves: Enhanced support for high-pressure operations.

• Integral Double Block and Bleed Ball Valves: Designed for critical isolation and safety applications.

Applications

More Info

- Oil and gas pipelines.

- Industrial gas distribution systems.

- Cryogenic applications in LNG facilities.

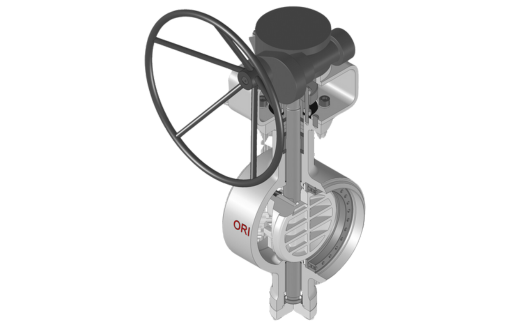

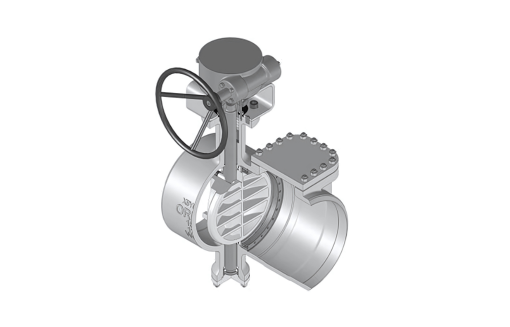

Butterfly Valves

Butterfly valves offer compact, lightweight solutions for large-diameter flow control with minimal pressure loss.

Key Features

More Info

- Space-saving design.

- Available in wafer, lug, and flanged styles.

- High-performance double-offset and triple-offset designs.

Applications

More Info

- HVAC systems.

- Water and wastewater management.

- Food and beverage processing.

Specialty Valves for Unique Applications

TISCO designs and manufactures specialty valves for demanding and niche requirements.

Key Features

More Info

• Cryogenic valves for ultra-low temperatures.

• Plug valves for abrasive and slurry services.

• Control valves for precise flow and pressure regulation.

Applications

More Info

• LNG and industrial gas processing.

• Mining and slurry transportation.

• Custom-engineered solutions for extreme environments.

Customer-Centric Philosophy

The foundation of our success lies in our unwavering commitment to our clients, guided by the Three S’s:

our products

Flanges

Flanges are mechanical components used to connect pipes, valves, pumps, and other equipment in various industries. They provide a secure and leak-proof joint, allowing for easy assembly, disassembly, and maintenance. Available in different types like weld neck, slip-on, and blind flanges, they are made from materials such as steel, stainless steel, and aluminum. Flanges play a crucial role in piping systems, ensuring structural integrity and efficient fluid flow.

Welding Neck Flanges

Welding Neck Flanges have a long tapered hub for strength and stress reduction, ideal for high-pressure applications. Used in oil, gas, and power industries, they provide smooth flow and minimal turbulence. Butt-welded to pipes, they ensure a strong, leak-proof joint.

Key Features

More Info

- Strong weld connection for high-pressure applications.

- Tapered neck design to reduce stress concentration.

Applications

More Info

- High-temperature and high-pressure pipelines in oil & gas industries.

- Power plants and chemical processing units.

Blind Flanges

Blind Flanges are solid, flat discs used to seal pipe ends or block flow in a piping system. They are ideal for high-pressure applications and allow easy access for maintenance or expansion.

Key Features

More Info

- No opening for flow; used to seal pipeline ends.

- Can be customized for pressure testing.

Applications

More Info

- Temporary or permanent pipeline closures.

- Maintenance and inspection points in refineries and plants.

Slip-On Flanges

Slip-On Flanges slide over the pipe and are welded in place for a secure connection. They are easy to install, cost-effective, and suitable for low-pressure applications.

Key Features

More Info

- Easy installation by slipping over the pipe.

- Lower cost compared to other types.

Applications

More Info

- Low-pressure systems in HVAC, water pipelines, and desalination plants.

- Food and beverage processing.

Lap Joint Flanges

Lap Joint Flanges are used with stub ends, allowing easy assembly, alignment, and disassembly. They are ideal for systems requiring frequent maintenance or adjustments. Common in low-pressure applications, they reduce welding costs and improve flexibility.

Key Features

More Info

- Used with stub ends for easy assembly.

- Suitable for applications where frequent disassembly is needed.

Applications

More Info

- Pipelines requiring corrosion-resistant materials.

- Offshore platforms and marine environments.

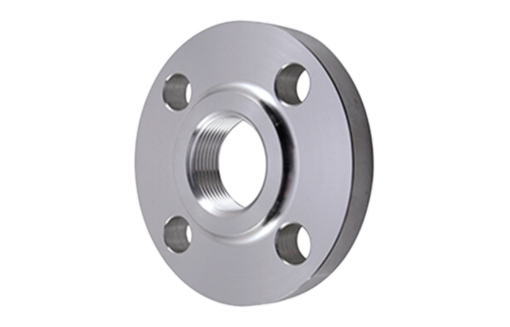

Threaded Flanges

Threaded Flanges have internal threads that allow them to be screwed onto pipes without welding. They are ideal for low-pressure, small-diameter applications and systems handling flammable substances. Common in plumbing and gas industries, they enable easy installation and maintenance.

Key Features

More Info

- No welding required; threaded for easy installation.

- Ideal for small-diameter, low-pressure systems.

Applications

More Info

- Utility services like air, water, and gas pipelines.

- Temporary connections in industrial setups.

Socket Welding Flanges

Socket Welding Flanges have a socket-shaped bore where the pipe is inserted and fillet-welded for a strong connection. They are ideal for small-diameter, high-pressure applications, providing smooth flow and reduced stress. Common in chemical and power plants, they ensure a secure, leak-proof joint.

Key Features

More Info

- Socketed design for a secure weld connection.

- Increased strength for small-diameter, high-pressure applications.

Applications

More Info

- Hydraulic and pneumatic systems.

- Steam and condensate systems in power plants.

Reducer Flanges

Reducer Flanges connect pipes of different diameters, ensuring smooth flow transition and minimal turbulence. They eliminate the need for separate reducers, saving space and installation time. Common in high-pressure and high-temperature systems, they are used in oil, gas, and chemical industries.

Key Features

More Info

- Allows connection of different pipe sizes.

- Maintains pressure integrity and flow dynamics.

Applications

More Info

- Oil and gas pipelines requiring diameter transitions.

- Industrial process systems.

Long Welding Neck Flanges

Long Welding Neck Flanges have an extended neck for added reinforcement in high-pressure and high-temperature applications. They provide a smooth flow transition, reducing stress and minimizing turbulence. Common in refineries, chemical plants, and pressure vessels, they ensure a strong, leak-proof connection.

Key Features

More Info

- Extended neck design for reinforcement.

- Ideal for extreme temperature and pressure conditions.

Applications

More Info

- High-pressure vessels and boilers.

- Cryogenic systems.

Orifice Flanges

Orifice Flanges are used with orifice plates to measure flow rates in piping systems. They have tapped holes for pressure sensors, ensuring accurate readings. Common in oil, gas, and chemical industries, they provide a reliable and efficient flow measurement solution.

Key Features

More Info

- Integrated design for flow measurement.

- Comes with pressure taps for differential flow readings.

Applications

More Info

- Flow monitoring in pipelines.

- Refinery and chemical plant systems.

Nipo-Flanges

Nipo-Flanges combine a weld neck flange with a small-diameter pipe connection, often used for branch connections. They ensure a strong, leak-proof joint in high-pressure piping systems. Common in oil, gas, and petrochemical industries, they simplify installation and improve flow efficiency.

Key Features

More Info

- Combines a flange with a nipple connection.

- Compact and efficient design.

Applications

More Info

- High-pressure piping systems.

- Steam and condensate lines.

Satisfaction Guaranteed

High-Performance Valves for Harsh Environments

“Our facility operates in extreme temperatures, and TISCO’s valves have proven to be incredibly reliable. Their corrosion-resistant coatings and precision engineering give us confidence in every application.”

Long-Term Reliability & Cost Savings

“Switching to TISCO valves has significantly reduced our maintenance costs. Their high-quality materials and craftsmanship ensure long service life with minimal downtime. A great investment for any industry!”

Satisfied

our products

Spacers and Rings

Spacers and Rings are used in piping systems to provide temporary or permanent gaps for maintenance, inspection, or flow regulation. Spacers maintain separation between flanges, while rings, like spectacle blinds, allow switching between open and closed positions. Common in oil, gas, and chemical industries, they ensure flexibility and control in fluid systems.

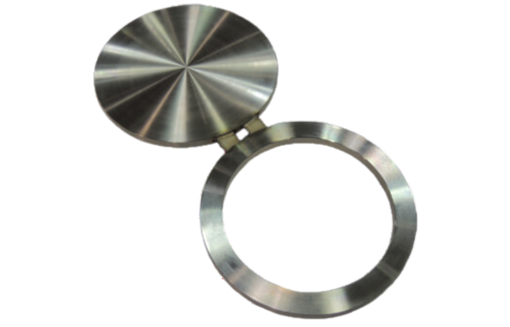

Figure-8 Blanks & Ring Spacers

Figure-8 Blanks and Ring Spacers are used to regulate flow in piping systems by alternating between open and closed positions. Figure-8 Blanks, or spectacle blinds, have one solid end to block flow and one open ring for passage. Ring Spacers replace the blind end when flow needs to be restored. Common in oil, gas, and chemical industries, they allow easy maintenance and system control.

Key Features

More Info

- Easily switches between open and closed positions.

- Suitable for isolating pipelines during maintenance.

Applications

More Info

- Offshore platforms and refineries.

- Safety-critical systems.

Blind Spacers

Blind Spacers, also known as paddle blinds, are solid discs used to completely block flow in a piping system. They are installed between flanges for isolation during maintenance, testing, or system shutdowns. Common in oil, gas, and chemical industries, they provide a secure and temporary seal.

Key Features

More Info

- Seals pipeline ends for maintenance and inspection.

- Heavy-duty design for durability.

Applications

More Info

- Petrochemical and oil refining units.

- Temporary closures in pipelines.

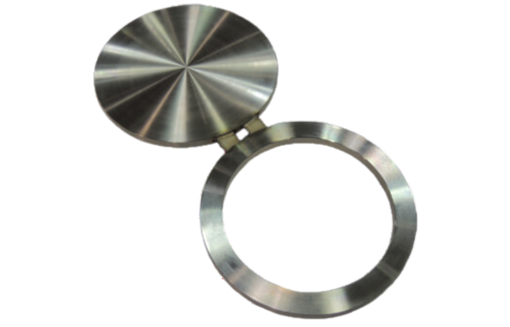

Blind and Ring Spacers

Blind and Ring Spacers, also called spectacle blinds, are used to alternate between blocking and allowing flow in a piping system. The blind spacer completely seals off the pipeline, while the ring spacer maintains flow. They are commonly used in oil, gas, and chemical industries for easy maintenance and system isolation.

Key Features

More Info

- Combines blind and spacer functionality for versatile use.

- Quick and easy to switch between operational modes.

Applications

More Info

- Power generation plants.

- Gas transmission systems.

Drip Rings

Drip Rings are installed in piping systems to collect and drain condensation or unwanted fluids. They help prevent buildup, protecting equipment from corrosion or damage. Common in steam and process piping, they ensure system efficiency and longevity.

Key Features

More Info

- Designed to collect or remove fluid in pipelines.

- Available in a variety of sizes and materials.

Applications

More Info

- Industrial drainage systems.

- Prevents fluid accumulation in sensitive areas.